One-Stop Cosmetic Bag OEM / ODM

Material Options for Custom Makeup Bags

At our factory, we provide a wide selection of materials to meet your custom makeup bag needs—helping your products look premium while staying true to your brand identity. With strong, long-term partnerships across China’s fabric supply chain, we have reliable access to a broad range of materials, including polyester, nylon, canvas, leather, cotton, jute, Tyvek, neoprene, PVC, TPU, recycled fabrics, and many other functional or specialty textiles—offering excellent value with stable quality.

Whether you’re creating luxury cosmetic bags with refined textures, or developing durable, practical designs for everyday use, we can recommend the right fabric to match your positioning and budget.

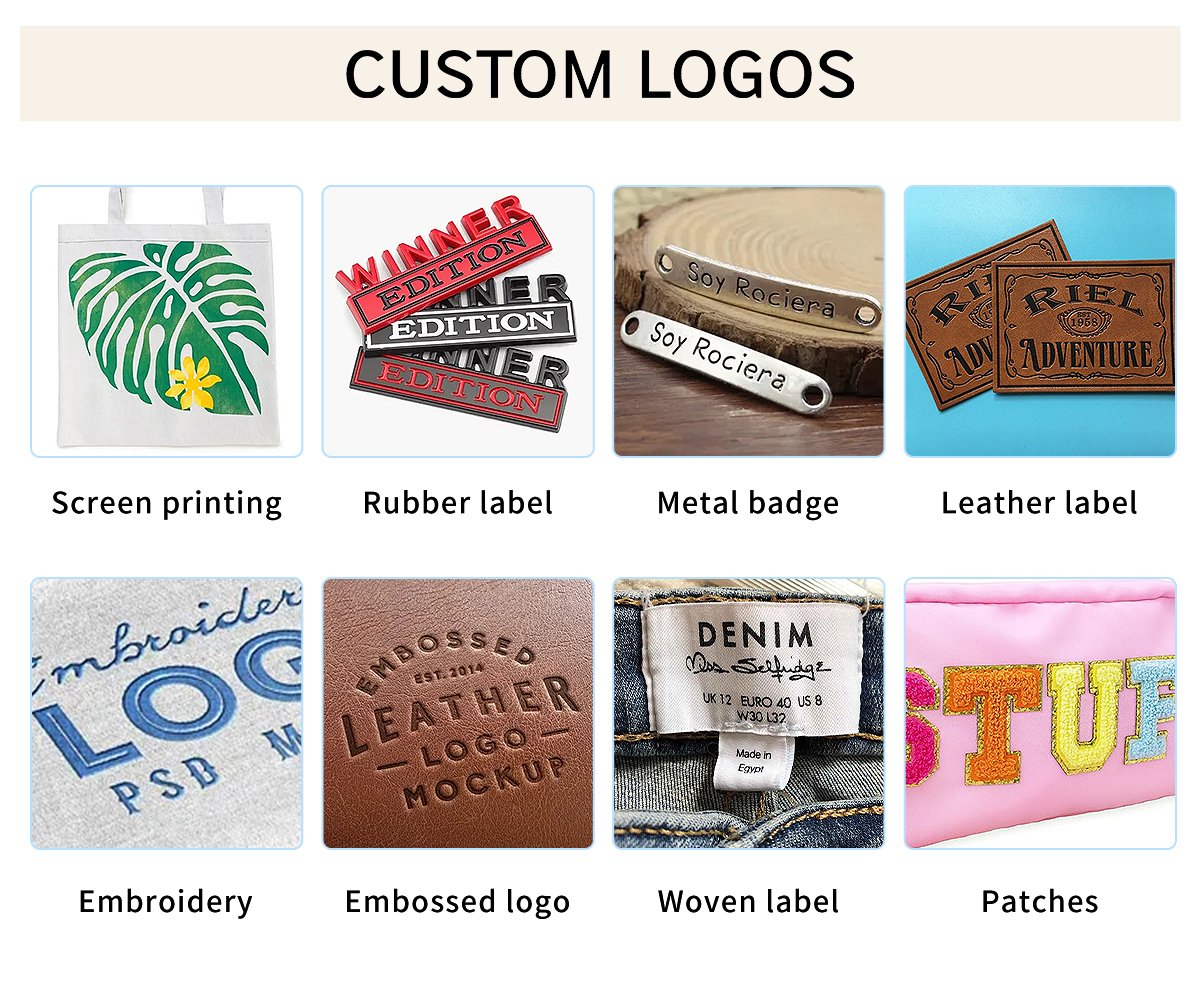

More Logo Options for Private Label

At our factory, we offer multiple logo techniques to match your private label style. With in-house embroidery, professional printing lines, and emboss/deboss machines, we make your logo look sharp, premium, and long-lasting—whether you prefer subtle elegance or bold branding.

Logo options: embroidery, printing (silk screen/heat transfer), emboss/deboss, woven label, rubber patch, metal logo, zipper pull logo.

Send us your logo file and preferred effect—we’ll recommend the best solution for your material and design.

Makeup Bags Manufacturing Processes From Our Factory

At our factory, quality drives every step of production. From material selection to final inspection, we follow a quality-focused production system with full process control to ensure consistent craftsmanship, reliable performance, and on-time delivery.

Fabric Selection

We source and verify fabrics based on durability, feel, color stability, and brand requirements.

Quality Check

Incoming inspection ensures fabrics and accessories match approved specs before production starts.

Fabric Cutting

Precision cutting improves consistency and increases material efficiency.

Printing

Logo and pattern printing is calibrated for sharp details and strong color adhesion.

Sewing

Skilled operators stitch panels with reinforced seams to support daily use and travel wear.

Sewing & Assembly

Hardware, lining, and zippers are assembled carefully to ensure smooth function and alignment.

Trimming

We trim threads, refine edges, and clean surfaces for a polished, retail-ready finish.

Quality Inspection

Final QC checks stitching, printing, dimensions, and functionality against the approved sample.

Warehouse

Products are packed, labeled, and stored safely for organized dispatch and on-time delivery.

Our Manufacturing Workshop

We manufacture a wide range of custom cosmetic bags for brands, retailers, and e-commerce sellers worldwide.

Punch press material cutting

Accurate cutting ensures stable sizing and clean edges for smooth follow-up sewing.

Sewing

Reinforced stitching on key panels improves durability and keeps the structure neat.

Sewing

Skilled operators ensure even seams, consistent alignment, and smooth finishing.

Screen printing

Clear logo printing with stable ink adhesion for long-lasting branding performance.

Embroidery

Premium embroidery for a textured, high-end look with excellent wash and wear resistance.

Quality inspection

Final inspection on stitching, size, logo, and function to ensure reliable quality before packing.